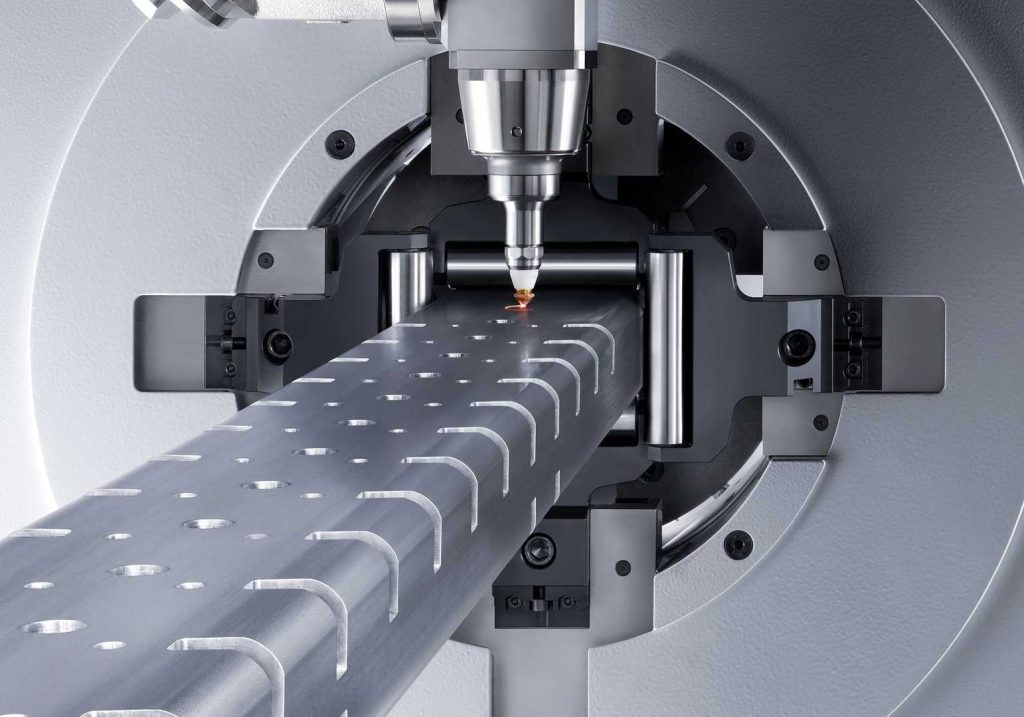

Wood restoration has long been a time-consuming and labor-intensive process, requiring hours of sanding, scraping, and chemical treatments. However, recent advancements in technology have revolutionized the way we restore wood, with metal sheet & tube laser cutting machines offering a faster, safer, and more efficient alternative.

The Advantages of Laser Cleaning for Wood Restoration

1. Faster, more efficient process: Laser cleaning is a faster and more efficient way to restore wood surfaces than traditional methods.

2. Greater accuracy: Laser cleaning offers greater accuracy and precision than traditional sanding and scraping processes.

3. Environmentally friendly: Laser cleaning is an environmentally friendly process that does not require harsh chemicals or abrasive materials.

4. Safe for use: Laser cleaning is a safe process, with no risk of injury or damage to the wood surface or surrounding environment.

5. Improved aesthetic: Laser cleaning can produce a more even, consistent finish than traditional sanding and scraping processes.

6. Cost savings: Laser cleaning can save costs due to less labour, faster process times, and no need for additional materials or equipment.

Conclusion:

Laser cleaning machines have undoubtedly revolutionized the wood restoration industry. With their ability to clean and restore wood surfaces quickly, efficiently, and safely, these machines have become an indispensable tool for wood restoration professionals. As technology continues to advance, we can expect even more innovative applications of laser cleaning in the field of wood restoration, further enhancing the preservation and beauty of wooden objects.