Industrial heat exchangers are a vital component of any manufacturing process. They are used to transfer heat from one medium to another, such as transferring heat from a hot liquid to a colder liquid, or from a hot solid to a colder gas. Heat exchangers are used in a variety of industries, including chemical, automotive, oil and gas, and food and beverage production.

Types of Heat Exchangers:

There are several types of finest industrial heat exchangers. The most common are plate-type, shell-and-tube, and regenerative exchangers. Plate-type exchangers are composed of a series of thin plates, which are connected to each other to form a single unit. These exchangers are efficient but can be difficult to clean.

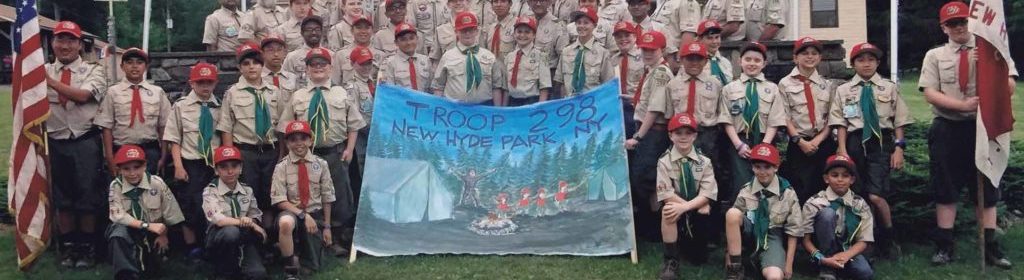

Image Source: Google

Shell-and-tube exchangers consist of two tubes that are connected to each other, with one tube containing the hot fluid and the other containing the cold fluid. Regenerative exchangers are used to transferring heat from a hot fluid to a colder fluid, but they require more space than other types of exchangers.

Benefits of Using Industrial Heat Exchangers:

Industrial heat exchangers provide several benefits to manufacturing processes. They can help to reduce energy costs by transferring heat more effectively than other methods. Heat exchangers also help to reduce emissions, since they can help to reduce the amount of energy that is wasted in the manufacturing process. Lastly, they are also able to improve the safety of workers by reducing the risk of accidents caused by overheating.